High Pressure Boilers

Introduction to Boiler

● According to Indian Boiler (IBR) Regulation Act 2007 - Boiler is a closed pressure vessel in which steam is generated with a capacity exceeding 25 liters, gauge pressure greater than or equal to 1 kgf/cm.sq, and water is heated at 100°C or above.

● In application where the 30 bar pressure and steam at rate 30 tons/hour is require the fire tube boilers are preferred due to low cost. In the power plant it is necessary to produce the steam at high pressure, high rate and high efficiency. So high Pressure Boilers are used to increases the efficiency of the plant. These are developed because of rising cost of fuel and restrictions on air pollution. Modern power generation plants generally use high pressure boilers. These high pressure boilers operates with a steam pressure above 140 bars and steam generation capacity 30 to 650 tons/hour and above with the temperature may be up to 540° to 610°C. It also reduces drum size. The high-pressure boilers are widely used for power generation in thermal power plants.

● High pressure boilers use both natural and forced circulations. Forced circulation is achieved with help of centrifugal pumps. By using this forced circulation, because of high velocity of water scale formation in the tubes and boiler drums is reduced.

● In a high-pressure boiler, if pressure on the feed water rises then saturation temperature of water increases and the latent heat of vaporization decreases.

● The feed water in a boiler is indirectly heated to saturation of temperature in the economizer by using waste heat recovery from the exhaust gases which is escaping to the chimney.

● Hence the heat required supplies to boiler is only latent heat of vaporization and superheat steam is obtained. Thus, for boiler operation at high pressure will require less heat addition for steam generation.

Characteristics Features of High Pressure Boilers :

Even though the modem boilers are termed as high pressure boilers, it does not mean them fully. Because high pressure operation is only one of the characteristics of modern boilers used for power generation.

High-pressure boilers have the following features:

a) Method of water circulation : The force of water circulation is increases and maintained with the help of centrifugal pumps which forces the water through the boiler plant. It increases the mean temperature of heat addition and evaporation capacity,

b) Improved method of heating : The heat transfer rate by radiation along with conduction and convection. The total heat-receiving equipment is divided into several parts. So they can easily be located in various zones of the furnace for most efficient heat transfer to the water circuit. the following methods for improved heat transfer rate:

1) Evaporation of water above the critical pressure of steam.

2) Heating of water by mixing superheated steam for high heat transfer rate.

3) Increasing the combustion of air velocity over the tube.

c) Type of tubing : The Large number of small diameter tubes are used so the ratio of surface area to volume (area density) increases. It helps in a high rate of the heat transfer to water flowing inside the tubes. Therefore, a large number of small density tubes are arranged in a zig-zag manner are used for water circulation in forced circulation. The use of a short tube have an advantage to reduces the pressure loss and keep the better control the quality of steam,

d) Pressurized combustion chamber : To improve the rate of combustion and thus increase the heat release rate, pressurized air is forces in the furnace with the help of force draft fan so a large amount of heat is produce in a small space.

e) Higher steam pressure and temperature: The steam is generated at a high pressure in the range of 80 to 300 bars and temperature of 450°C to 585°C the two super-heaters are used in series. The use of such steam is very suitable for power generation. It increases the thermal efficiency of the plant and reduces the moisture contents in low-pressure stages of expansion in the turbine.

f) Compact size: The high rate of heat transfer inside the boiler reduces the overall size of the boiler, and the boiler becomes compact.

g) Intensive heating : The furnace temperature in high pressure boilers is high enough and therefore, 70% of heat is transferred to water by radiation. This is a faster way of heat transfer.

h) High efficiency : These boilers have better firing methods, monitoring, furnace conditions, control flue gases and water velocity.

i) Once through construction : These are operating at and above the critical pressure so the water directly flashes into steam in the tube itself. It eliminates the need of a boiler drum.

Advantages of High Pressure Boilers:

The following advantages are listed:

1. Because of high velocities, tendency of scale formation in the tubes is reduced.

2. Small light weight tubes of better heating surface arrangements can be used. This makes the unit compact and reduces erection time and cost of boiler.

3. Due to forced circulation, for heating of all the parts is uniform, which avoids over heating and development of thermal stresses

4. of thermal stresses. There is more flexibility in the arrangement of furnace, tubes and other boiler components.

5. The steam can be raised quickly to meet the variable load requirements without the use of complicated control devices.

6. The efficiency of the plant is increased by 40 to 42%

7. A very rapid start from cold is possible if an external power supply is available. Hence the boiler can be used for carrying peak loads or standby purposes with hydraulic power stations.

8. All the part are uniformly heated therefore danger of overheating is reduces and thermal stress problem is minimized

9. They require less heat of vaporization.

Classification of High Pressure Boilers :

The modern high pressure boilers are classified into different types of as listed below:

A) Type of high pressure supper critical boiler

1.Lamont Boiler

2. Benson Boiler

3. Loeffler Boiler

4. Schmidt-Hartmann Boiler

5. Velox Boiler.

6. Supercritical Boiler.

7. Supercharge Boiler.

8. Fluidized bed combustion Boiler.

B) High pressure boilers can be further classified into

1. Natural circulation,

2. Forced circulation and

3.Once through boilers

Lamont Boiler

● A forced circulation boiler was first introduced in 1925 by Lamont. It is a forced circulation high pressure water tube boiler. This is generally used in Europe and America.

● The feed water from hot well is supplied to a storage and separating drum (boiler) through the economizer.

● The most of the sensible heat is supplied to the feed water passing through the economizer.

● A centrifugal pump circulates the water equal to 8 to 10 times the weight of steam evaporated. This water is circulated through the evaporator tubes and the part of the water evaporated is separated in the separator drum.

● The steam separated in the boiler is further passed through the super heater and finally supplied to the prime mover.

|

| Lamont Boiler |

● These boilers have been built to generate 45 to 50 tons of superheated steam at a pressure of 120 bar and at a temperature of 500°C.

● The advantage of this boiler is that it is flexible, compact and small size of drum.

● But the disadvantage of this boiler is formation of bubbles on inner surface of the tube reduces heat transfer and steam generation rate. as it offers high thermal resistance than water film.

● This further increased the danger of overheating the tubes due to salt deposition as it has high thermal resistance.

Benson Boiler:

● The main difficulty experienced in the Lamont boiler is the formation and attachment of bubbles on the inner surfaces of the heating tubes.

● The attached bubbles to the tube surfaces reduced the heat flow and steam generation as it offers high thermal resistance than water film.

● The presence of steam bubbles in contact with the surface of tubes seriously impairs heat transmission from the flue gases to water.

● It is the first boiler to be designed for operation above critical pressure

● By rising the boiler pressure to the critical pressure of steam (225 kgf/cm.sq), this difficulty is overcome, as suggested by Mark Benson in 1922

|

| Benson Boiler |

● At the critical pressure water and steam have the same density and no bubbles are formed. Further at critical pressure the enthalpy of evaporation (Latent heat) is zero. The water thus gets converted into steam directly without passing through evaporation process,

● The first modern high pressure drumless boiler developed by Benson was put into operation in 1927 in west Germany power station.

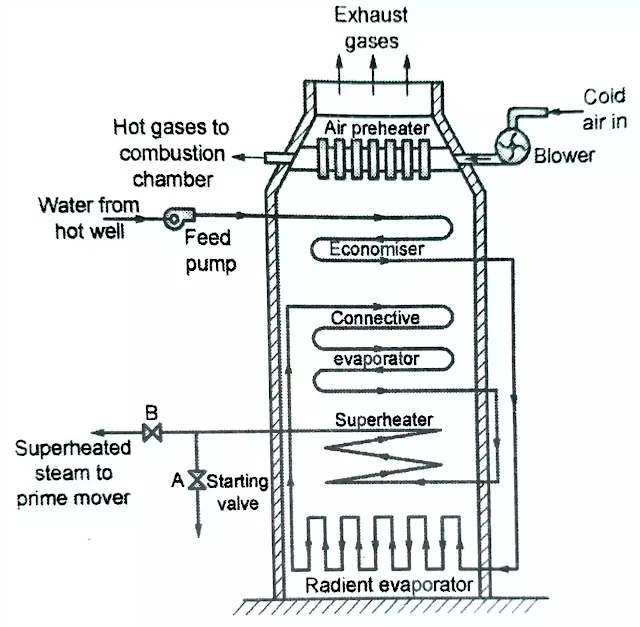

Working Principle of Benson Boiler:

This boiler has a unique characteristic of absence of steam separating drum. The entire process of heating, steam generation and superheating is done in a single continuous tube

(a) Economiser :

● The feed water by means of the feed pump is circulated through the economiser tubes.

● Hot flue gases pass over the economiser tubes and the feed water is preheated.

● The feed water from the economiser flows into the radiant evaporator with radiant parallel tube sections.

● The radiant evaporator receives heat from the burning fuel through radiation process and majority of water is converted into steam in it.

● But rising of water to a pressure of about 221.2 bar will means large pump work and the efficiency of plant may reduce.

(b) Radiant evaporator :

● In this section most of the heat is transmitted and water gets and remaining water is evaporated heated almost to the critical temperature. (Water cooled walls from the portion of section) absorbing the heat from the hot gases by convection and radiation

● Thus the saturated high pressure steam at a pressure up to 250 bar is obtained and much more.

(c) Convection super-heater:

● The saturated steam is now passed through the convection super-heater where the saturated steam is superheated to 650°C.

● The radiant evaporator, the convection evaporator and the convection super-heater are all arranged in the path of the flue gases.

(d) Steam outlet :

● The superheated steam is supplied to the steam turbine through the steam outlet.

● The uniform final steam temperature over the range of output can be attained by series arrangement of radiant and convective super-heater component.

(e) Capacity :

● Capacity of Benson boiler is about 135000 kg/hour at a pressure of 250 bar and at a temperature of 650°C. (Efficiency may be improved by running the boiler at a pressure slightly lower than the critical pressure).

● Supercritical pressure plant works at higher efficiency of about 40%

● In supercritical boilers plant 65% of heat is transferred in superheating of steam and reheating of steam bled from steam turbine at intermediate pressure.

● Also to limit gas temperature a radiant super-heater is used.

Salient Features of Benson Boiler:

1. As there are no drums, the total weight of Benson boiler is 20% less than other boilers. This also reduces the cost of the boilers.

2. As no drums are required, the transfer of the Benson parts is easy. Majority of the parts may be carried to the site without pre-assembly.

3. Since no drum is used, this is an once-through boiler and the feed water entering at one end is discharged as superheated steam at the other end.

4. Circulating pump and down comers are dispensed with.

Advantages of Benson Boiler:

1. As there are no drums, the total weight of Benson boiler is 20% less than other boilers. This also reduces the cost of boiler.

2. Natural circulation boilers require expansion joints but these are not required for Benson as the pipes are welded. The erection of Benson boiler is easier and quicker as all the parts are welded at sites and workshop job of tube expansion is all together avoided.

3. The transfer of Benson's parts is easy as no drums are required and majority of the parts are carried to the site without pre-assembly

4. The Benson boiler can be erected in a comparatively smaller floor area. The space problem does not control the size of Benson boiler used.

5. The furnace walls of the boiler can be more efficiently protected by using smaller diameter and closed pitched tubes.

6. The super-heater in the Benson boiler is an integral part of forced circulation system, therefore no special starting arrangement for super-heater is required.

7. The Benson boiler can be started very quickly because of welded joints.

:)

:) :(

:( =(

=( ^_^

^_^ :D

:D =D

=D =)D

=)D |o|

|o| @@,

@@, ;)

;) :-bd

:-bd :-d

:-d :p

:p :ng

:ng